Our history

The beginning

The original owners of FUNDICIONES JULCAR worked in a low-pressure foundry using the gravity die casting in a warehouse in the centre of Burgos. A few years later the opportunity aroused them, and they finally took over the business.

1980: First changes

In 1981, two families decided to create FUNDICIONES JULCAR. They bought the first Zamak pressure injection machine and the first aluminium pressure injection machines. These were the beginnings that gave rise to the first customers in the automotive sector.

Since 2000: New divisions and extensions

In 2000, JULCAR HERRAJES began over due to the business vision of the founder together with the commercial department who saw a potential business line that could be explored and be profitable. As a result, they invested in the development of our own range of products by creating our own moulds and establishing contact with external suppliers to increase our product range and cover a wider catalogue.

In 2002 the first expansion of the factory took place in order to adapt us to market needs as a result of the increase in customers, buying new machinery and increasing our workforce.

In 2014, the acquisition of a three-dimensional machine streamlined part measurements.

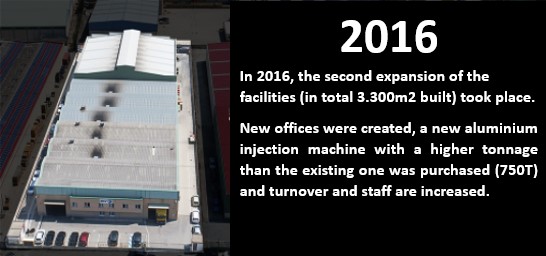

In 2016, the second expansion of the facilities (in total 3.300m² built) took place to continue with the experienced growth in recent years and to opt for a higher turnover. New offices were created, a new aluminium injection machine of higher tonnage was purchased (750T) and again we increased our workforce.

In 2017, JULCAR continued with its policy of continuous improvement, investing in the quality department with the acquisition of an X-ray machine.

In 2020, the ARNAIZ family took over the company as sole owner. After that, a new aluminium injection machine of greater tonnage (1250T) and a new bridge crane were acquired, in order to keep meeting the requirements of our customers who request more complex and larger parts. And to continue streamlining part measurements, we added the option to scan the parts on our three-dimensional machine.