Die Casting

Since our beginnings, the foundry has been the main nucleus of our activity.

Actual parts typology

Endowed with a very important degree of automation, we serve our customers parts with the following characteristics:

|

Material |

Aluminium and Zamak high-pressure die-casting |

|

Piece size |

From 10gr up to 2.5kg |

|

Anual series |

From 30,000 to 800,000 parts/year (depending on the part size) |

Machinery

We have specialized machinery of different tonnages, both for zamak and aluminium, which allows us to manufacture a very wide range of parts.

|

Aluminium |

Machine from 160T to 1250T |

|

Zamak |

Machine from 80T to 220T |

Sectors

|

Automotive (85%) |

Our main clients nationally and internationally are Tier 1 and Tier 2. |

|

Hardware/Metalwork (12%) |

Handles, Cremones, Pre-frame squares, Glazing blocks, etc. |

|

Others (3%) |

Valves, furniture, construction, cosmetics, electricity, etc. |

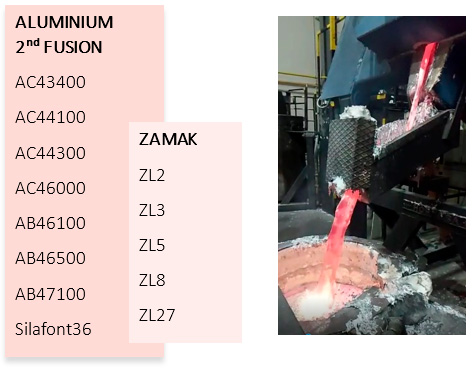

Alloys

In order to give the best service to our clients, JULCAR offers a wide range of alloys whose mechanical characteristics are different and are adapted to any of their projects.

The raw material plays a fundamental role in the internal quality of the part, for this reason, JULCAR systematically controls the chemical composition of each of its alloys upon receipt by spectrometer.