Tooling manufacturing and validation

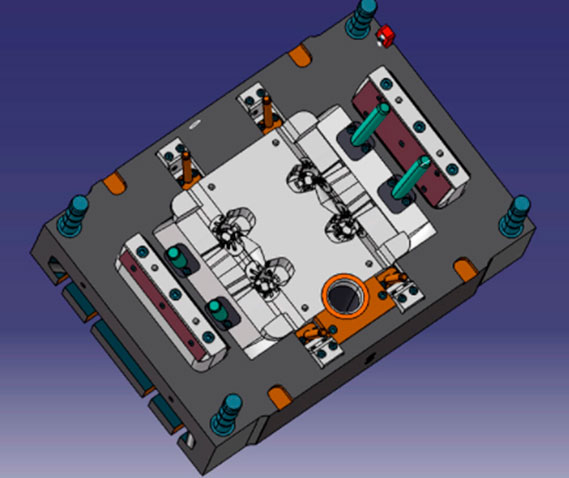

Mould definition: Injection moulding consists of the high-pressure injection of raw material into a mould that shapes the part. Moulds can be single cavity or multiple cavities. They are constructed of special high-strength steels to withstand high closing and injection pressures for a limited production.

Die cut / Trimming cut definition: It is a cutting-edge tool that, by means of a press system, serves to cut the contour of the part and clean any hole and / or window using inclined guides if necessary.

Runner definition: The runner itself is a component of the injected part but it is not part of the part. The runner channels are where the injected material circulates. The channel section is the point where it joins the mould cavity(ies) and we will call raw material entry.

Based on our experience, on the morphology of the piece, on its requirements (porosity, break test, etc.), and on whether the piece is safety, we understand that the design of the casting and the tooling is essential to ensure that our pieces are of high quality.

For this reason, after the close collaboration with our suppliers, we always validate the 3D of the runner, the mould and the die cut before starting the tooling manufacture.

At all times, JULCAR monitors the progress of the tooling manufacturing to ensure that the deadline provided to our client is met.