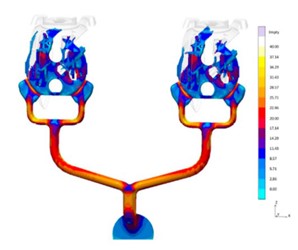

Filling simulation

The filling simulation provides detailed information on the filling and solidification of the casting while tracking defects that may occur, such as for example porosity, trapped air and bubbles, stresses and thermal deformations among others.

The filling simulation allows us to foresee possible:

- Areas difficult to fill

- Areas to be cooled or tempered

- Lacks of fulfilment or compaction problems

For this reason, for the most complex parts, JULCAR usually performs simulations prior to the manufacture of the tools since it allows us to make the necessary improvements, either by redesigning the runner and / or adding overflows to achieve a suitable filling.